Automated washing machines are broadly split into two types – conveyor (tunnel) machines and single tank machines.

Conveyor Machine

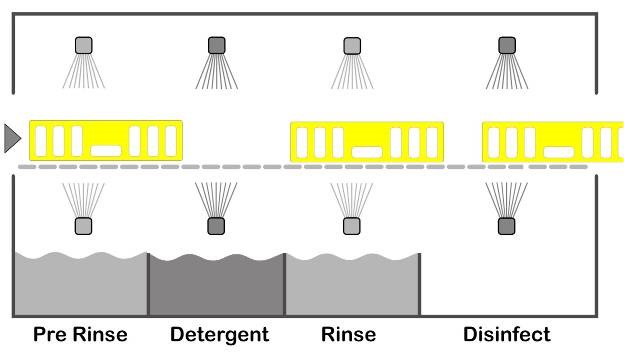

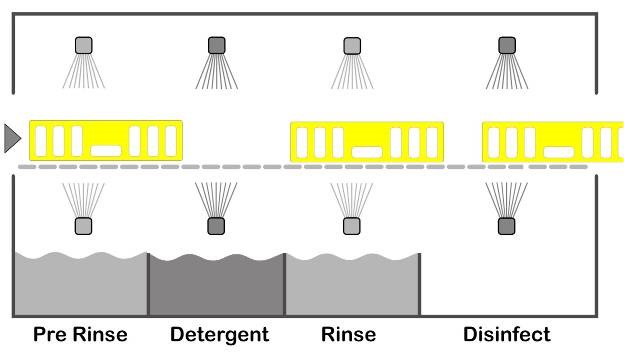

The schematic shows a 3-tank conveyor tray wash with a disinfect section. Configurations of tray wash machines will vary dependant on the specified requirements.

Conveyor Wash Process

Items are placed on a conveyor which transports them through the various stages of the washing process, with each stage occurring in a different section of the washer; pre-rinse, wash with detergent, rinse, disinfect chemically or thermally and then dry.

- The pre-rinse is fed from the overflow from the final rinse and disinfectant tanks.

- The recirculating detergent solution is commonly a low foaming detergent appropriate to the equipment being cleaned and the nature of the soiling. Caustic based detergents are usually the most efficient and cost-effective types of detergents used for this method of cleaning. A chlorinated detergent must not be used >50°C as it can attack stainless steel. A neutral or inhibited detergent may be employed for cleaning of sensitive items, such as aluminium or Teflon coated trays.

- The final rinse section is general a fresh water feed which is then recovered to the pre-rinse section.

- The disinfectant should ideally be applied, without recirculation, as a fine spray or mist and at a flow rate to not over-wet the trays. This solution after contact with the trays is commonly collected and returns into the rinse tank.

- The drying stage where applicable is normally carried out via high velocity warm air blowers.

Smaller tunnel washers are based on the same principle but leave out certain sections. Typically, smaller washers are configured with a detergent section and a hot water final rinse section (sometimes in excess of 82°C to achieve thermal disinfection).

Two or more operators are typically needed for this type of tray wash machine.

Single Tank (Rack, Utensil, Dolav & Bin) Washers

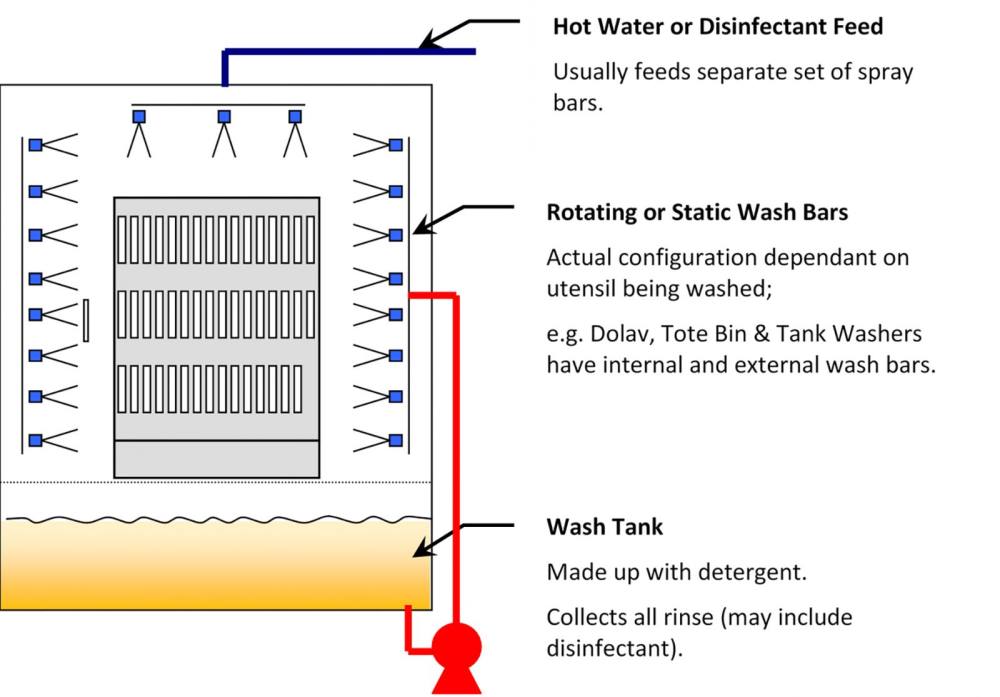

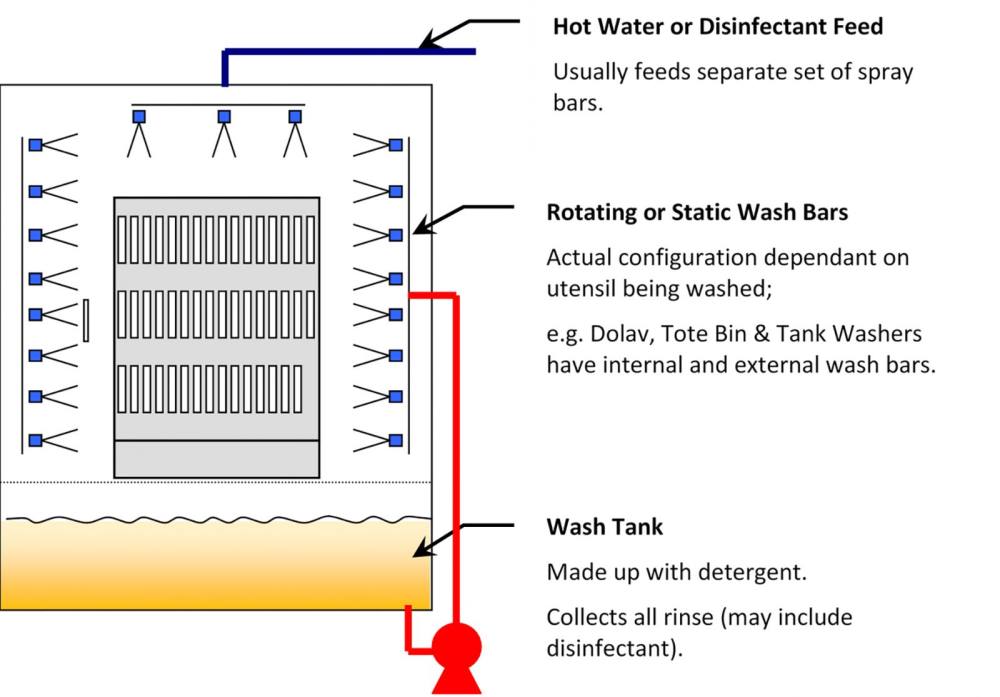

The configuration shown is typical of a rack washer. Configuration of washers will vary. Note: These types of machines are usually fitted with a rotating jet in the centre to clean interior surfaces.

Rack Washer Process

- With single tank machines, the item is placed in a cabinet and the wash process takes place in the cabinet by sequencing the cleaning stages: pre-rinse, wash, rinse and disinfect.

- All solutions used end up in the wash tank and as such a level of fresh make up is needed so that the tank overflows diluting the soil levels in the tank. This fresh make-up is the final clean water or disinfectant rinse. Because of the addition of this ‘fresh water’ detergent needs to be dosed on each cycle in proportion to the rinse water volume.

One operator is usually needed for this type of automated washing machine.

Cross contamination in washing machines

In both types of washing machines, certain cleaning solutions are reused (e.g.detergent), which can become a vector for allergen transfer. This is one of the reasons why it is important to have a clean water or disinfectant feed for the final rinse and it should be sufficient in volume to rinse away any debris and detergent on the item being washed. It is important that the whole washing process is validated for both microbial cleanliness (if appropriate) and freedom from allergens.

Location & Environment

Washing machines and their locations should:

- Be in a separate room having sufficient space to allow adequate separation of dirty and clean trays/equipment.

- Have sufficient ventilation for the area and the machine taking steam vapours directly to the exterior of the factory.

- Be well lit with suitable lighting (LED lighting is more cost effective). This assists the operatives with visual inspection of items being cleaned and maintaining the environment to an appropriate standard.

- If necessary, the volume of air extracted should be matched by an air make-up supply to prevent excessive negative pressure in the area.

- Have fabrication of the same standard as the rest of the factory for the area.

- Have sufficient drainage for the area.

- Enforce the same hygiene and safety rules employed across site.

- Have a logical flow from ‘dirty’ to ‘clean’ areas (care should be taken where carousel types are in operation).